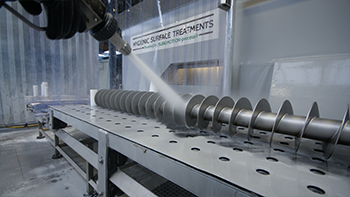

Because of the many years of experience built up in the food and pharmaceutical industries and the knowledge that the current legislation in respect of food production is becoming ever more stringent, we offer our customers a high-quality surface-treatment technology; this is consistent with the high-quality and high-end products that we manufacture and finish. This technology is offered in the form of the SUBLIMOTION-process®. The surface treatment of these products by means of wet abrasive blasting (SUBLIMOTION-process®) is key to the final result. The products have to comply with all hygienic properties and the ease of cleaning in its entirety has to be optimal. This surface treatment process has the following properties:

- Improved surface topography / roughness <0.6 Ra

- Optimal corrosion resistance (anti-corrosive)

- Controlled surface peening (sealing fine cracks)

- Hydrophobic (water-resistant) properties

Quite simply: reduced adhesion properties and optimum ease of cleaning!

Within the food industry, there has to be a constant and specific focus on hygiene, because consumers expect high-quality food products which are produced safely. This means that all machinery that comes into contact with those food products has to be free from all types of soiling and microbial contamination. That is why various regulations and directives have to be complied with:

- EN1672-2: Food processing machinery / General Basic Rules / Part 2: Hygiene requirements.

- EN ISO 14159: Hygiene requirements for the design of machinery

- 2006/42EG: Machinery directive

- Regulation (EC) 1935/2004: food contact materials and articles

- EHEDG Guidelines (European Hygienic Engineering and Design Group)

The SUBLIMOTION-process® is a technology that has the following exceptional advantages:

- It is a one-step-process; everything takes place in one single treatment

- The process enables effective cleaning and results in a very fine finish (Ra values <0,6)

- The same values of the surface roughness are generated in all directions, resulting in an isotropic surface.

- The surface is thoroughly cleaned and any hairline cracks are sealed by the build-up of compression stress (peening) on the surface.

- Optimal corrosion resistance.

- After treatment, the surface has hydrophobic properties.

- No iron contamination occurs during the process.

- The process uses an inert cleaning suspension consisting of water and inert microparticles.

- The process is ecological and is based on a sustainable technology (Green Process).

CONTACT ME

Linkedin

Linkedin